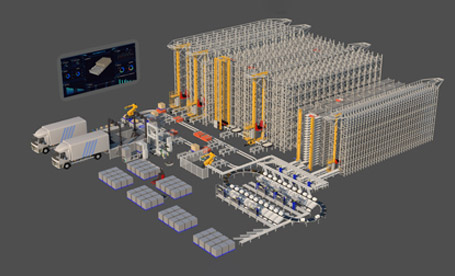

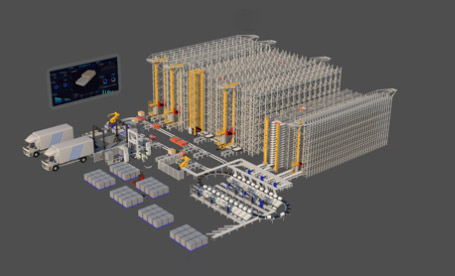

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

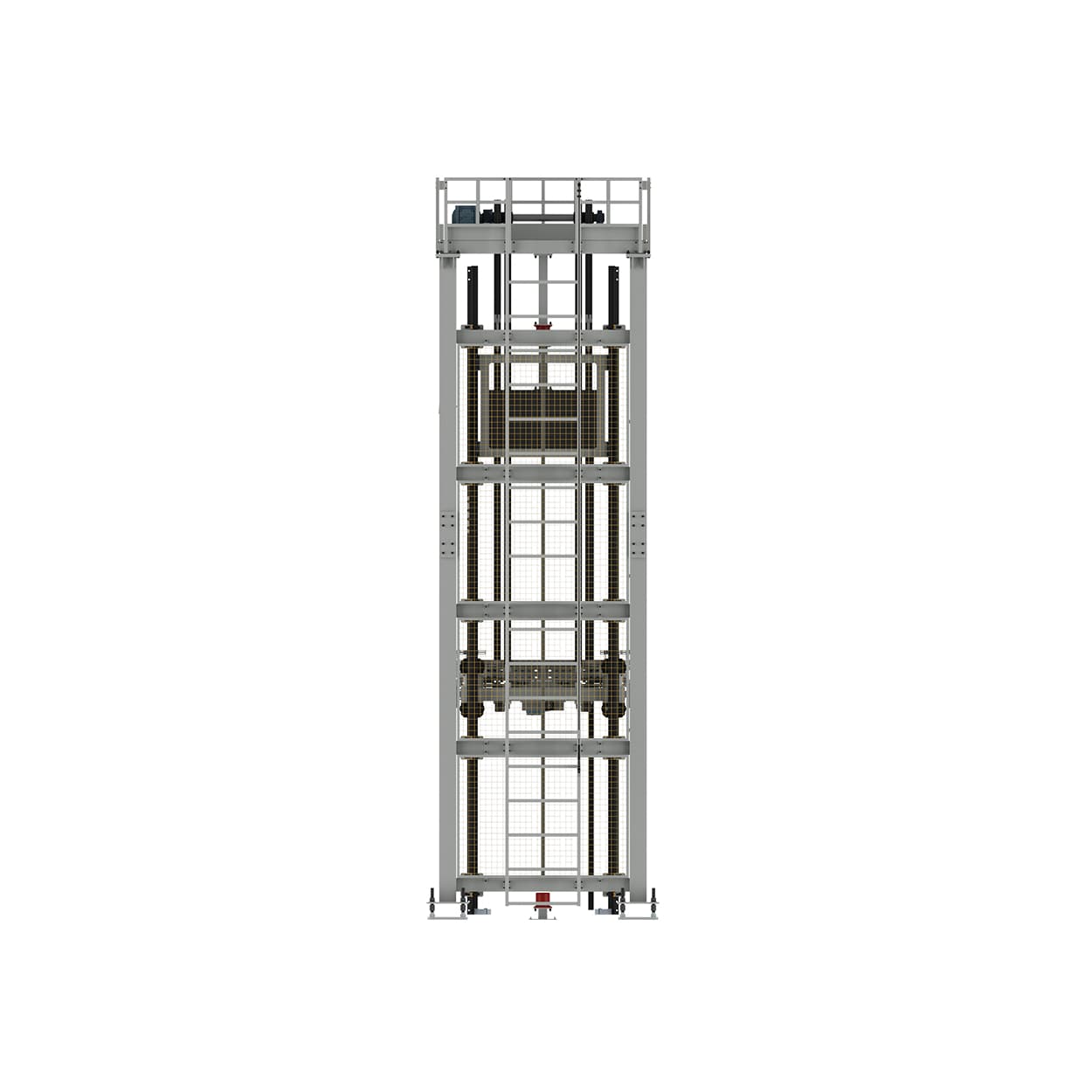

Learn MoreThe DELIECN High-Speed Lifter is designed for efficient cargo and shuttle transport within AS/RS systems. Its precise vertical movement ensures seamless shuttle integration for high-speed material handling. Tailored to your load profile and operational needs, it enhances warehouse automation and supports flexible, intelligent operations.

Chain Lifting System

Positioning Accuracy (±2 mm)

Enhanced Safety

Cost-Effective

Operating Temperature: -25℃~+40℃

Compact design to minimize footprint and optimize space utilization.

Features advanced speed control technology for fast and stable layer changes.

Designed to accommodate large volumes of inbound and outbound goods, it significantly enhances operational efficiency and reduces costs.

Easy Maintenance: The simple control program contributes to a lower failure rate, enhancing ease of maintenance.

The pallet lifter is composed of an outer frame, a cabin, a telescopic fork, a counterweight, a power supply system and control system etc. Through the telescopic fork structure, goods can be picked up and placed smoothly. At the same time, with the cabin rising and falling, it can carry the goods or the shuttle robot to reach the designated floor.

Learn MoreThe high-speed tote lifter lifts the totes to the designated layer of the AS/RS warehouse rack by operating the lifting and lowering of the cargo loading station to realize the layer-changing operation of the totes.

Learn MoreThe landing lifter is composed of a main frame, a lifting cabin, conveying equipment, a top lifting drive component, a control system, etc. It lifts and lowers the target material to the appointed height through the lifting cabin, thereby realizing the transition of the material to the lower-end equipment.

Learn More

Pallet/Tote shuttle Lifter

High Speed Tote Lifter

Landing & Lifting Machine

Finished goods warehouse

Connected with the raw material warehouse, production line and finished product warehouse

18 set of unit-load crane applied

Storage capacity: 29,000 pallet positions

High efficiency: 44,800 cartons/day

Finished goods warehouse

Connected with the production line

Multi-equipment applied (Crane, Shuttle, Robot arm, RGV etc.)

Storage capacity: 550000+ pcs

High throughput: 50,000 pcs/day

Height: 22 m

Space utilization increased: by 50%

Customize the logistics robot equipment with high adaptability

Achieve the unified full process unmanned management from the production line to the storage