Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

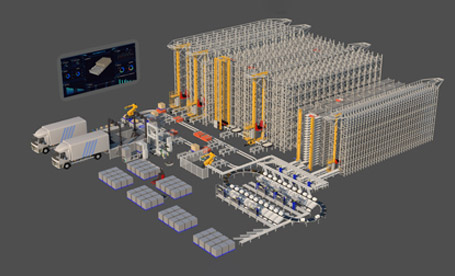

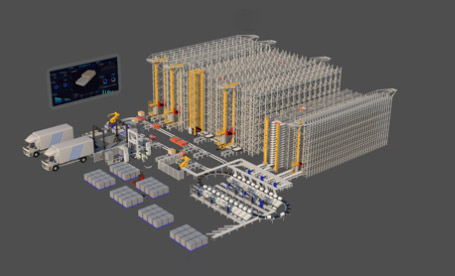

Learn MoreAS/RS warehouse is an important part of modern logistics system, and its core operation processmainly includes receiving, shipping and picking. The following is a detailed introduction to theoperation process.

1. Receiving process

Receiving preparation and goods acceptance

Warehouse management system (WMS) receives receiving instructions from upstream systemsincluding information such as goods type, quantity, and expected arrival time.Warehouse managers plan the storage location in advance according to the receiving instructionsto ensure that there is enough storage space for new goods.

After the goods arrive at the warehouse, they are quickly identified and the quantity of goods isverified through automatic identification technologies such as barcodes, RFlD tags, and QR codesAutomated receiving operation.

The goods are placed on the conveyor belt, weighed, scanned, and other necessary steps, andthen sent to the designated aisle.

The stacker or shuttle moves precisely to the designated storage location above according to theWMS instructions.

The stacker or shuttle safely and accurately places the goods on the shelf by performing actions such as lifting and sliding.

WMS automatically updates inventory information, including the location, quantity, and status of the goods.

2. Picking operation process

Order processing

When a customer places an order, Wis automatically plans the picking route according to theorder information and generates picking tasks.

Automatic pickingThe stacker, takes the reguired goods from the shelf according to the instructions of WMs andplaces them on the designated outbound platform.

The automatic guided vehicle transports the goods from the outbound platform to the sorting platform.

On the sorting platform, the goods are sorted by workers or automatic sorting equipment according to the outbound order.

After the sorting is completed, the automatic guided vehicle returns the goods to the entrance of the lane or directly outbound.lfthe goods need to be put into the warehouse, the stacker repositions the goods on the shelf

3. Outbound operation process

Outbound order reception

WMS receives the production line or customer goods demand information pushed by ERP

Outbound order planning

WMS automatically performs inventory gueries and generates pickingtasks based on the principles of first-in-first-out, equal distribution, and proximityWMS arranges the stacker, operation sequence according to the current outbound operationsituation and the stacker,status, and sends the arranged operation instructions to thecorresponding stacker.

Goods out of the warehouse

The stacker takes the goods from the shelfand places them on the outbound platform.After the goods are scanned and confirmed again at the outbound entrance, they are loadedonto the transport vehicle and sent to the destination.

WMS upd ates the goods information and shelf occupancy in the inventory database based on theinformation fed back by the control system.

In summary, the AS/RS operation process is highly automated and intelligent, which can greatlimprove the storage efficiency and operation efficiency of the warehouse. At the same timeWMS optimizes inventory layout and predicts inventory demand through real-time monitoringand data analysis, providing decision support for procurement and sales.