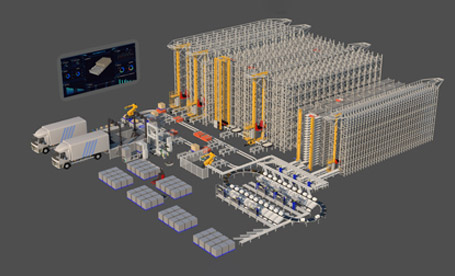

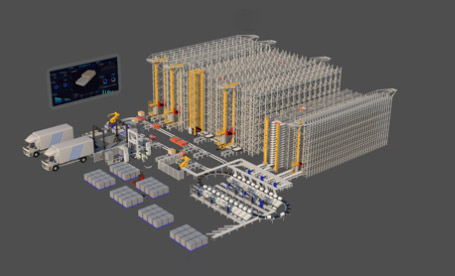

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

Learn MoreAuthor: Mr Zha from Deliecn ——Reflections from a recent automation project

Over the past few years, while working on automated warehouse projects for mechanical manufacturing enterprises, I have repeatedly encountered the same challenge:

As production capacity expands, traditional storage models — floor stacking combined with forklift handling — quickly become a limiting factor rather than a support.

What initially looks like a warehouse issue often turns out to be a system-level problem between storage, handling, and production logistics.

This became especially clear during a recent automotive components manufacturing project I was involved in.

What I Observed on Site

Before automation, materials were stored in steel cages and stacked directly on the floor.

Internal transport relied heavily on manual forklifts.

This resulted in several typical issues:

• Low space utilization and limited vertical expansion

• High labor intensity and increased safety risksssss

• Disordered material placement and slow retrieval

• Manual paperwork and fragmented information management

As production volume increased, these issues began to directly affect line feeding efficiency and overall operational stability.

Automation Is Not Just About Storing More

In this project, the goal was not simply to introduce automated storage equipment.

What really mattered was integrating warehouse storage and production-line distribution into one coordinated system.

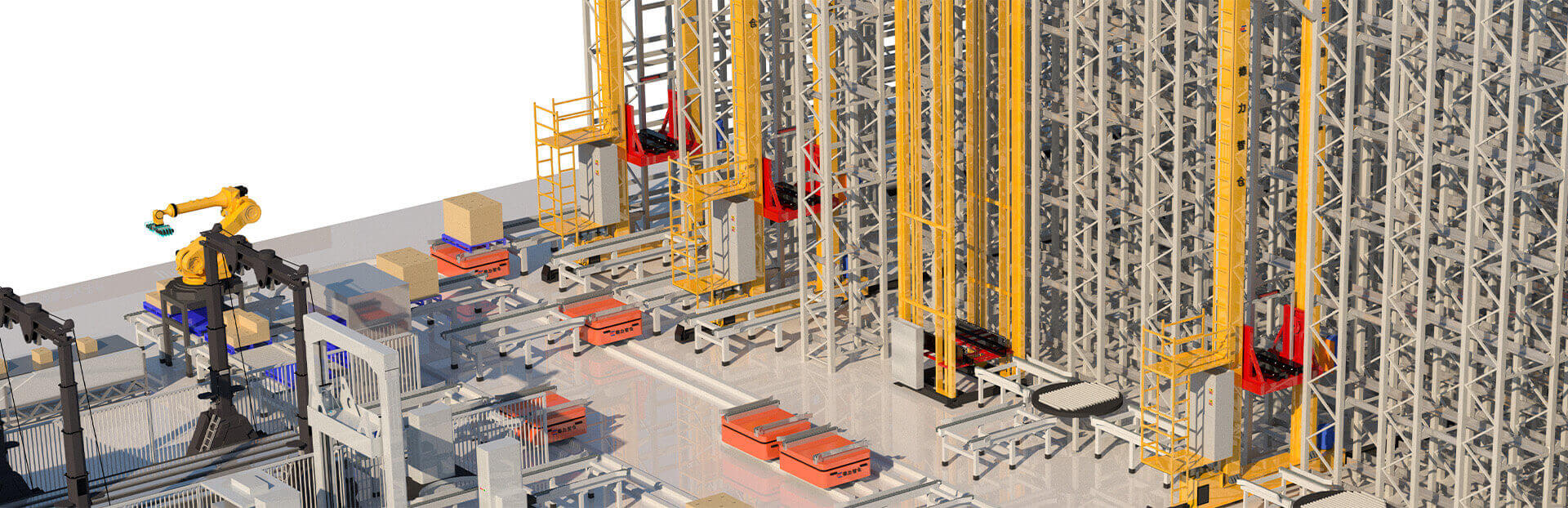

During planning and design, we focused on:

• High-density vertical storage to improve space utilization

• Stable heavy-load handling suitable for industrial components

• Coordinated operation of AS/RS, four-way shuttle robots, lifters, conveyors, and AGVs

• Centralized scheduling and control through WMS and WCS

Only by treating storage and production logistics as a single system could efficiency improvements be sustainable.

Results After Implementation

After the automated warehouse system went live:

• Storage space utilization increased by approximately 300%

• Inventory and operation accuracy reached 99.99%

• Manual handling requirements were reduced by around 80%

• Inbound storage, outbound handling, and line-side delivery became fully automated

From my perspective, the most valuable outcome was not just higher efficiency, but a more stable and predictable production rhythm.

Forklifts were gradually removed from congested production areas, and material flow between the warehouse and production lines became consistent and controllable.

My Key Takeaway

One conclusion became very clear to me through this project:

Automation in mechanical manufacturing is no longer about individual machines or isolated technologies.

It is about system integration, process continuity, and long-term operability.

When warehouse storage and production logistics are planned together from the beginning, automation becomes a foundation for sustainable manufacturing — not just a short-term efficiency upgrade.