Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

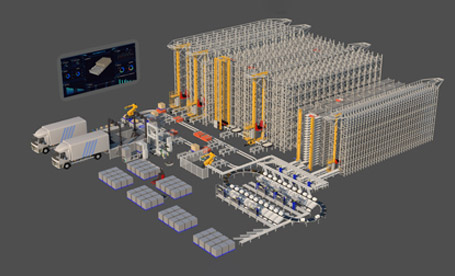

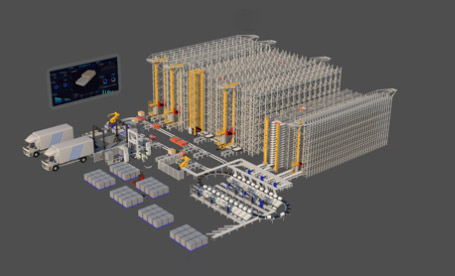

Learn MoreManufacturers and 3PLs are expanding SKU ranges, facing volatile order profiles, and operating under tighter space and labour constraints. In this environment, automated storage and retrieval systems (AS/RS) deliver speed and consistency—but the next performance leap comes from AI-driven orchestration.

AI does not replace automation. It improves how automation performs by enabling real-time decisions, predictive inventory logic, and continuous optimisation across warehouse operations.

Even advanced AS/RS projects can be limited by static rules when conditions change. AI helps automated warehouses handle:

A modern AI-enabled architecture is typically built on four layers: WMS (warehouse management), WCS (warehouse control), equipment execution, and digital twin visibility.

The WCS maintains a live operational map of equipment status and task flows. AI-based routing and scheduling can:

This supports consistent throughput under complex, multi-vehicle conditions.

By integrating WMS with ERP/MES and order streams, AI can improve:

In shuttle-based AS/RS, performance depends on how well fleets are coordinated. AI scheduling can:

Digital twin tools create a real-time, data-driven view of the warehouse and can be used to:

A pallet four-way shuttle solution with 40,000+ pallet positions uses AI-enabled WCS scheduling to coordinate dozens of shuttle robots in clustered operations—supporting high storage density while maintaining stable throughput.

A tote stacker crane AS/RS integrated with identification tracking (e.g., RFID) supports real-time material visibility and adaptive storage strategies for raw materials, WIP, and finished goods—especially in high-mix environments.

A hybrid AS/RS combining stacker cranes and tote shuttle systems uses digital twin modelling to deliver full operational visibility and traceability—supporting compliance-oriented workflows and controlled warehouse operations.

As AI capabilities mature, automated warehousing is moving toward software-defined intralogistics—systems that self-optimise based on live data, evolving order profiles, and operational constraints.

For operators, the goal is practical: higher resilience, better utilisation, and scalable performance—without adding complexity to daily operations.