Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

Learn MoreA major food and feed processing enterprise—renowned for its large-scale operations in edible oils and animal feeds—has taken a bold step toward smart logistics by collaborating with Deliecn Intelligent Warehousing. With an annual processing capacity of 300,000 tons of oilseed and 240,000 tons of feed, the enterprise offers a wide range of products, including plant-based edible oils and specialized feed for livestock, aquaculture, and pigs.

As product lines expanded and production capacity grew, the company faced increasing complexity in material distribution and warehouse management. To overcome these challenges and stay ahead in a highly competitive market, the enterprise partnered with Deliecn to launch a comprehensive renovation and automation of its aging warehouse infrastructure. The goal? To build a next-generation automated high bay warehouse system that enhances capacity, boosts efficiency, and ensures food safety through digital traceability.

• Maximize warehouse spacethrough high-density storage by upgrading existing flat-floor warehouses.

• Au tomate the full warehouse workflow—from inbound raw materials to outbound finished products—to reduce labor intensity and increase operational accuracy.

• Enable intelligent inventory controlwith traceable data for food safety compliance and eliminate inconsistencies between stock records and actual inventory.

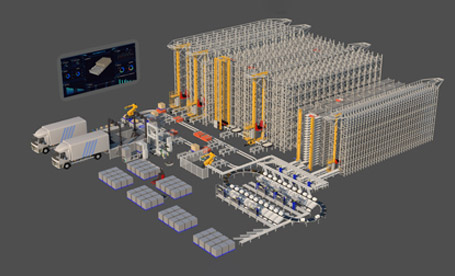

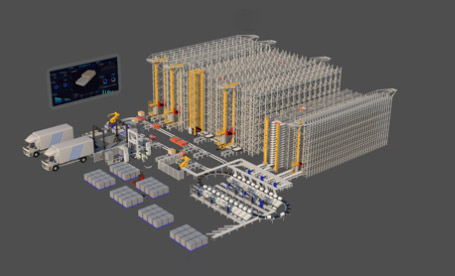

After thorough on-site evaluation, Deliecn’s engineering team proposed a customized four-way shuttle system specifically designed for the food and grain industry. The solution includes:

• Four-way pallet shuttle robots

• RGV rail-guided shuttles

• Vertical lifts for layer exchange

• Warehouse Control System (WCS)

•Warehouse Management System (WMS)

• Pallet racking and conveyor systems

This integrated solution allows seamless material flow, end-to-end automation, and scalability to support future growth.

An overhead corridor was constructed to connect the oil packaging line directly to the smart warehouse, allowing finished goods to be automatically transported via RGV rail-guided vehicles between two warehouse zones. This reduces manual handling, shortens transportation time, and increases overall logistics speed.

Twelve four-way pallet shuttles work in coordination under the WCS system to meet high-frequency inbound and outbound operations. The system ensures precise, real-time handling of materials across aisles, levels, and zones. With 24/7 automation, the warehouse supports continuous and uninterrupted order fulfillment.

Despite the constraints of the existing facility, Deliecn implemented a four-level high-bay racking system with fire-zoned partitions, enabling over 3,800 storage positions and accommodating up to 180,000 items of various SKUs. The space utilization rate exceeds 90%, supporting the client’s expanding capacity. Additionally, a built-in water mist fire suppression system ensures maximum safety.

The combined use of RGV systems and four-way shuttle robots allows for fast, safe, and efficient material movement. Inbound capacity reaches 55 pallets/hour, while outbound speeds exceed 100 pallets/hour. Compared to the manual model, operational efficiency has improved by more than 50%, while labor intensity and safety risks have been significantly reduced.

The advanced WMS enables full traceability of each batch, including source and production data—ensuring compliance with food safety regulations. Real-time updates allow for one-click inventory checks, improving record accuracy to 99.99%. This digital platform empowers better production planning, optimized inventory management, and smarter supply chain decision-making.

This successful transformation of a legacy warehouse into a fully automated smart logistics hub marks a major step forward in the company’s digitalization journey. The project not only unlocks greater storage capacity and productivity, but also enhances food safety, reduces reliance on labor, and positions the client for sustained growth in a competitive market.

As a trusted provider of automated warehouse solutions, Deliecn Intelligent Warehousing continues to lead innovation in smart logistics, having delivered over 1,000 projects across industries such as food and beverage, pharmaceuticals, new energy, and heavy industry. With cutting-edge robotics and software integration, Deliecn remains the go-to partner for manufacturers seeking to embrace Industry 4.0.

Deliecn is a full-service provider of smart warehousing and logistics automation solutions. With over a decade of expertise, the company specializes in automated storage and retrieval systems (AS/RS), robotic shuttle technologies, and integrated WMS/WCS software. From consulting and design to implementation and support, Deliecn empowers enterprises to optimize logistics, improve ROI, and accelerate digital transformation.