Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

Learn More“Wanquan International Advanced Titanium and Titanium Alloy Materials Manufacturing Industrial Park” is a flagship project by Shaanxi Wanhao Titanium Special Materials Technology Co., Ltd. (Wanhao Titanium). Situated in the Baoji Comprehensive Bonded Zone, this project involves a total investment of RMB 1.2 billion (~US$165 million), spans over 300 acres, and includes 100,000 square meters of modern production facilities.

The industrial park focuses on producing advanced titanium materials and high-precision titanium components, serving industries such as aerospace, shipbuilding, nuclear power, and precision manufacturing. To align with the high-tech demands of its facility and enhance warehouse efficiency, Wanhao Titanium partnered with Deliecn Intelligent Warehousing to implement a turnkey automated warehouse logistics system specifically designed for the non-ferrous metals industry.

•Space Limitations: Raw materials were previously stacked directly on the ground, consuming valuable floor space.

•Low Turnover Efficiency: Manual handling and long transport routes delayed material flow and affected productivity.

•Heavy Manual Labor: Titanium’s heavy weight placed a burden on workers, increasing safety risks and lowering efficiency.

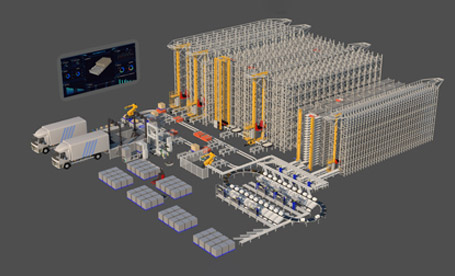

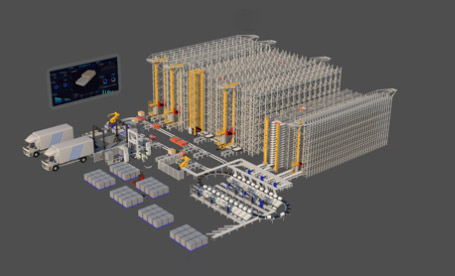

Deliecn delivered a 17.7-meter-high automated high bay warehouse (AS/RS), featuring:

•Stacker cranes designed in-house

•High-precision racking systems

•Automated Guided Vehicles (AGVs)

•Gantry robots

•A smart warehouse software suite including Warehouse Management System (WMS) and Warehouse Control System (WCS)

The system supports over 2,000 storage locations and can store more than 2,000 tons of titanium sponge, achieving up to 5x higher space utilization compared to traditional warehouse layouts.

Customer Feedback:

“We used to rely on people running around the warehouse to locate materials. Now, everything is digitized and automated. We can check real-time inventory data and the whole logistics flow is significantly more efficient.”

•Deliecn’s proprietary stackers support up to 1,125 kg per pallet, achieving 30 pallets/hour throughput — a 50% improvement in operational efficiency.

•High-speed barcode readers ensure accurate material tracking and instant data updates in the WMS.

•The WCS platform orchestrates conveyors, AGVs, and gantry robots, enabling up to 40 automated material movements/hour with minimal human error and enhanced safety.

•Materials automatically transfer from the warehouse to production feed points, streamlining processes and reducing labor reliance.

•Time-phased task scheduling avoids congestion — warehousing, picking, and pallet returns operate on separate timelines for maximum uptime.

This project successfully integrates automation, digitization, and intelligent control, setting a new benchmark in the titanium supply chain. Key benefits include:

•Significant increase in warehouse utilization

•Improved labor productivity and safety

•Real-time, traceable inventory management

•Enhanced resilience and responsiveness across the entire production process

Deliecn Intelligent Warehousing is a global leader in warehouse automation with over 1,000 successful AS/RS projects in industries such as aerospace, new energy, cold chain, pharmaceuticals, food and beverage, and heavy manufacturing.

With over a decade of experience, Deliecn provides end-to-end smart logistics services — from system planning and production to on-site commissioning and after-sales support. Backed by cutting-edge robotics and AI, Deliecn is the one-stop automation partner for companies advancing into the Industry 4.0 era.