Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

Learn MoreHenan Ru Yang Dukang Liquor Co., Ltd. is one of China’s most renowned modern distilleries, covering a total area of 1.56 million square meters. With an annual production of 80,000 tons of solid-state liquor and 30,000 tons of food-grade alcohol, the company is a key player in China’s export market, serving regions such as Russia, Europe, and Southeast Asia. As the company’s sales surged year after year, the complexity and volume of its logistics operations increased, demanding a shift from traditional warehouse methods to a fully automated, intelligent solution.

To support its future growth and align with high-quality development goals, Deliecn Intelligent Warehousing was chosen to implement a smart, automated high-bay warehouse system, focused on enhancing product flow, digitalizing storage management, and improving operational efficiency.

1、Maximizing Space Utilization: Achieving geometric improvements in storage space efficiency.

2、Digital & Smart Operations: Fully integrating intelligent storage and logistics management across all warehouse processes.

3、Order Processing Capacity: Handling more than 50,000 boxes/day to meet growing demand and minimize errors.

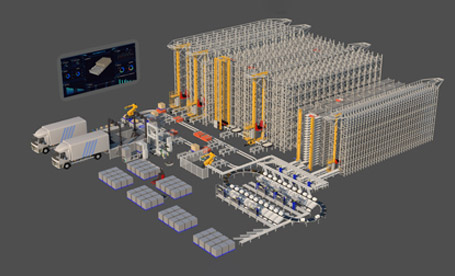

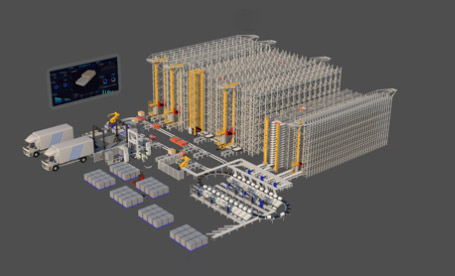

Deliecn’s team meticulously analyzed Ru Yang Dukang’s production and storage needs, providing a customized high-density automated warehouse solution. This included stacker cranes and shuttle robots, along with Deliecn’s WMS (Warehouse Management System), WCS (Warehouse Control System), and ECS (Electric Control System).

The smart warehouse measures 84m × 81.1m × 12m, with 11044 storage locations, a capacity to store 500,000 units, and operating in a temperature range from -10°C to 40°C. It includes 4 aisles, 4 layers of racking, and is equipped to handle material unit weights of over 1000kg.

The system is designed for seamless integration with production lines, offering features such as automatic palletizing, intelligent sorting, and precise scheduling, ensuring the highest levels of efficiency and low storage costs.

Once products are packaged, the ERP system communicates production status to the WMS, generating an inbound task. After visual inspection, the items are automatically conveyed to the warehouse, where a robotic arm handles palletizing. The stacker cranes and shuttle robots work together to store the products in specific locations.

The WMS generates an outbound order, which is dispatched to the WCS. The shuttle robots and stacker cranes execute the retrieval task, moving products via the conveyor system to the forklift station, where they are transferred to the loading platform. During peak periods, the system can anticipate high demand and manage pre-storage in a buffer area.

1、Scalability: The system design allows for easy expansion, adding palletizing stations as production lines grow.

2、Efficiency Gains: A closed-loop transport system minimizes costs and maximizes material handling speed.

3、Precision Engineering: Key areas such as the product release stations and robot tracks are customized to ensure stability and accuracy.

4、Reliability: Multiple devices in each aisle act as backups, ensuring consistent performance.

Before the upgrade, Ru Yang Dukang’s 6,500 square meters of space could hold only 150,000 to 200,000 units. After implementing the automated warehouse system, the storage capacity increased to over 500,000 units. The project achieved:50% savings in labor costs

1、3X improvement in warehouse throughput

2、3X increase in storage capacity

3、99.99% operation accuracy

By adopting Deliecn’s intelligent warehouse solution, Ru Yang Dukang accelerated its digital transformation, improving both operational efficiency and cost management. Additionally, the system extended the company’s value chain, enhancing product competitiveness in the global market.

This project represents a significant leap forward in Ru Yang Dukang’s logistics transformation, showing how smart warehousing and automation can drive efficiency, reduce costs, and ensure scalability. Deliecn continues to lead the way in enabling intelligent logistics solutions for the food and beverage industry, helping companies transition to a digitally connected and automated future.

As a leader in warehouse automation, Deliecn Intelligent Warehousing has over 1,000 successful smart warehouse projects worldwide. Specializing in automated storage and retrieval systems (AS/RS), shuttle systems, and warehouse management software, Deliecn offers complete, end-to-end solutions for clients across industries such as food & beverage, pharmaceuticals, new energy, and manufacturing.