Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

Learn MoreA leading large-scale modern liqu or manufacturer in China, operating across over 16.8 million square feet of production space and producing over 176 million pounds of liquor annually, sought to transform its traditional warehousing operations. With a growing international presence and increased logistics demands, the company partnered with Deli Smart Warehousing to implement a fully integrated automated storage and retrieval system (AS/RS), streamlining inventory handling and enabling digital, intelligent warehouse management.

1、Maximize space efficiency—achieving multiple times the storage capacity within the same footprint.

2、Digitize and automate warehousing operations, including storage, retrieval, and transport.

3、Boost throughput to 50,000+ cases per day, improving order fulfillment accuracy while reducing operational costs.

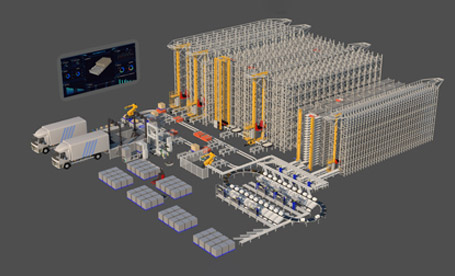

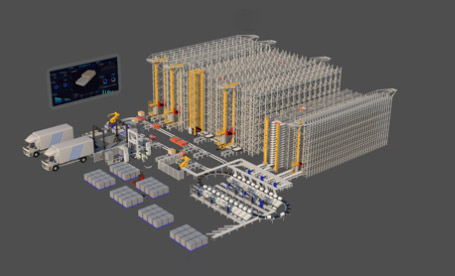

Deli delivered a customized high-density pallet storage system based on the client’s site layout and logistics requirements. The integrated solution features:

– Proprietary WMS (Warehouse Management System)

– WCS (Warehouse Control System) and ECS (Electrical Control System)

– Shuttle racking system

– 4 single-deep stacker cranes

– 8 bidirectional pallet shuttle robots

– 1 robotic palletizer and depalletizer

– 1 Rail Guided Vehicle (RGV)

– Conveyor lines and supporting components

The intelligent warehouse covers an area of 276 ft × 266 ft × 39 ft with 4 aisles and 4 levels, providing 11,044 active pallet positions. Each pallet slot accommodates loads over 2,200 lbs and supports goods sized up to 49.2″ × 41.3″ × 75.2″. The warehouse maintains a temperature-controlled range of 14°F to 104°F and offers a total storage capacity exceeding 550,000 cases, with inbound/outbound throughput surpassing 50,000 cases per day.

– Automated storage zone

– Outbound conveyor and dispatch area

– Production packaging area

– Temporary unloading buffer

– Automated palletizing & depalletizing area

The system combines hardware and software with intelligent scheduling to ensure seamless integration across processes—achieving fully automated receiving, storage, order picking, and shipping operations.

The ERP system triggers WMS to initiate inbound tasks. Finished goods are scanned, measured, and automatically conveyed to robotic palletizing. Stacked pallets are transported to the warehouse entry point, where stacker cranes and shuttle robots place them in designated positions. All data is synchronized in real time with the WMS.

Outbound orders are received by the WMS and translated into execution commands. The WCS coordinates cranes and shuttles to retrieve goods, which are then conveyed to forklift pickup stations. During peak shipping periods, goods may be staged in temporary buffer zones to improve outbound response time.

• Scalability: Designed with expansion in mind—more palletizing stations can be added as production grows.

• Efficiency: Closed-loop conveyor design minimizes handling time and improves material flow.

• Customization: Tailored robot track and pallet handoff zones ensure operational precision and system reliability.

• Redundancy: Multiple devices per aisle offer backup support, ensuring uninterrupted high-throughput performance.

Before automation, the original 70,000 ft² space held 150,000–200,000 cases. Now, with Deli’s intelligent solution, capacity exceeds 550,000 cases. Additional results include:

• 50% reduction in labor costs

• 3× increase in inbound/outbound efficiency

• 3× increase in storage capacity

• 99.99% operational accuracy

By adopting Deli’s smart warehousing solution, the client has accelerated its digital transformation—achieving leaner operations, lower costs, and enhanced value throughout the supply chain.

This project highlights Deli Smart Warehousing’s expertise in delivering intelligent, high-density warehousing solutions for the liquor and beverage industry. With over 1,000 successful AS/RS installations globally, Deli offers end-to-end services—including system design, implementation, commissioning, and long-term support.

As industries worldwide seek digital transformation and operational excellence, Deli continues to lead the way in providing scenario-based, customizable automation solutions tailored to each customer’s needs.