Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

Learn MoreWhen a manufacturing plant expands, logistics complexity often grows faster than building area. That is especially true for equipment manufacturers running mixed-model production: bulky materials must move safely, while small parts with high SKU diversity must be delivered in the right sequence—often across multiple floors.

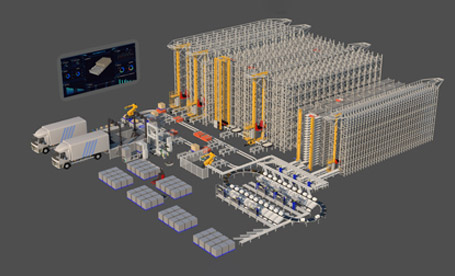

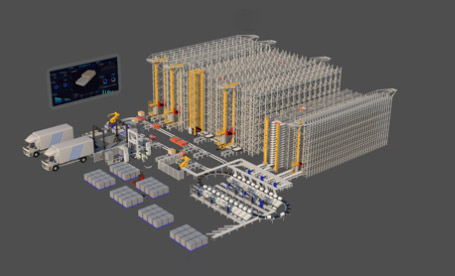

In this project, a global compressor and pump equipment manufacturer planned a new factory with smart manufacturing as a core objective. DELIECN engineered a hybrid internal logistics system combining pallet storage automation and tote storage automation, designed to support kitting completeness, JIT delivery, and multi-floor line feeding without relying on manual handling as volumes scale.

The target was not only higher storage density, but also controllable production supply:

1、Serve lines on two floors with coordinated replenishment

2、Separate heavy and small parts flows while keeping scheduling consistent

3、Reduce waiting and buffering uncertainty at line-side handover points

4、Link warehouse and production data via WMS and ERP/MES connectivity

DELIECN structured the program around two complementary subsystems:

The pallet AS/RS uses a single-rail dual-stacker-crane layout to fit the restricted site conditions while enabling parallel operations.

Project configuration highlights:

For the long tail of parts, the tote AS/RS provides:

Carrier circulation can become a hidden bottleneck. In this program, pallet carriers were routed with a split-flow design:

The customer focused on density, speed, and accuracy while maintaining traceability:

For equipment manufacturing plants that must feed lines across floors and handle mixed materials, the “pallet + tote” pattern is widely applicable because it: