Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

Learn MoreAt present, many manufacturing workshops handle cast components with irregular shapes that must be placed on specially designed pallets. These components are typically transported and stacked in designated areas using manually operated forklifts, while inventory is recorded manually. For large and heavy tractor castings—such as engine housings and gearbox housings—forklift stacking at height poses significant safety risks. Manual handling of high-quality cast components also increases the likelihood of damage. In addition, manual inventory records suffer from low accuracy and poor timeliness. The stacking method used in dedicated classification areas leads to inefficient utilization of vertical space and low turnover rates, resulting in overall poor space utilization.

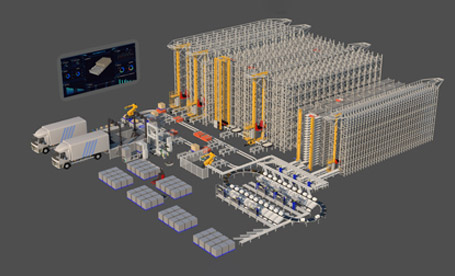

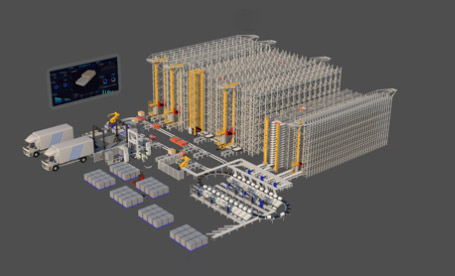

To address these issues, it became imperative for the factory to adopt an automated storage and retrieval system (AS/RS). By automating the handling, cleaning, inbound and outbound operations, and storage of cast components throughout the workshop processes, the factory aimed to improve warehouse turnover efficiency and operational safety, reduce operating costs, and achieve informatized, automated, and lean warehousing management.

Cast housing parts such as engine housings and gearbox housings are large in size and require high quality standards. Manual forklift handling involves high operational risks and significant labor intensity. Traditional warehousing methods occupy large areas, offer low turnover efficiency, and provide insufficient inventory visibility. Therefore, it was necessary to design and implement an automated, intelligent storage system capable of accommodating multiple product types and sizes.

Given the specific requirements of this automated handling system, double-mast stacker cranes were selected to enhance operational safety and reliability. The stacker cranes utilize vector closed-loop variable-frequency control, achieving high-speed operation while preventing load instability.

The lifting mechanism adopts a brake-equipped spiral bevel gear right-angle motor reducer that directly drives the drum. Steel wire ropes move the load platform vertically. Both fixed and movable pulleys are made from engineering-grade nylon, resulting in low noise operation and easier maintenance, with visible inspection of wire rope wear. The wire ropes are designed with a safety factor of 10, and the customized high-strength steel wire ropes provide a safe service life of 4–6 years. Overspeed braking devices and detection systems are installed, ensuring lifting safety comparable to elevator standards.

Latent-type AGVs are deployed at the AS/RS entry and exit points as well as at interfaces with various workshop processes. Their primary function is to automatically connect operators with production lines, washing lines, and the automated warehouse.

During inbound operations, operators place housing parts onto pallets. AGVs transport the pallets to the automatic marking area, where gantry robots pick the workpieces and load them into the marking machine. After marking, a turnover device flips the workpieces, and gantry robots place them onto empty pallets supplied by AGVs. The AGVs then transport the pallets to a semi-finished buffer area. When required for machining, AGVs deliver the pallets to the processing workshop. Upon completion, the pallets are transported to the washing workshop. After washing, AGVs deliver the pallets to the AS/RS inbound lifting conveyor, which automatically transfers them to designated storage locations via stacker crane operation.

During outbound operations, the stacker crane places the pallets onto conveyors at the exit, where they wait for AGV transport to the assembly workshop.

Warehouse Management System (WMS)

Warehouse Control System (WCS)

AGV Control System (RCS)

These systems jointly manage storage location allocation, process node coordination, and material handling efficiency. They record all operational events and track production, assembly, inbound, and outbound status in real time. The system interfaces seamlessly with the enterprise’s ERP, Manufacturing Execution System (MES), and downstream receiving departments. Task routing guidance enhances picking accuracy and efficiency, ensuring improved production performance.

Traditional storage of cast housing parts presents several challenges:

• Limited pallet standardization

• Insufficient vertical utilization and wide logistics aisles

• Low automation level

• Low informatization level

To reduce pallet variety and maximize standardization, a universal pallet design was developed for cast housing parts. Racking systems were designed in two standardized dimensions to accommodate multiple product specifications. A four-level AS/RS configuration was adopted to maximize vertical space utilization.

AGVs were introduced to reduce logistics aisle requirements. WMS and WCS systems were deployed to automate warehouse operations, enabling real-time monitoring and control of all equipment. FIFO logic was enforced by integrating processing and assembly stations.

During inbound operations, operators request empty pallets via PDA. Material barcodes are printed using laser marking machines, and materials are bound to pallets by quantity. Without human intervention, materials are automatically transferred between production, washing, and assembly processes. The AS/RS software automatically assigns storage locations and records inventory data. During outbound operations, designated pallets are retrieved from the AS/RS, and inventory records are automatically updated.

Electrical control cabinets are installed along the AS/RS wall with dedicated personnel access aisles. Control cabinets are equipped with touchscreens, key switches, status indicator lights, fault indicators, and audible alarms, operated by trained technicians.

When operating in automatic mode, stacker cranes execute WCS commands without manual intervention. To ensure personnel and equipment safety, the following measures were implemented:

• Comprehensive hardware and software safety protection with electrical interlocking

• Travel, lifting, and extension limit photoelectric sensors

• Forced deceleration functions to prevent excessive speed

• Dual-position detection with load presence verification

• Entry dimensional inspection to prevent mismatched storage

• Overload and slack-rope protection (triggered at 1.5× rated load or loss of tension)

• Dedicated pedestrian safety aisles and human–machine separation in AGV zones

• Three-color signal lights on all equipment to indicate operational status

Since commissioning, the automated cast housing parts storage system has successfully achieved integrated automation across production, washing, and assembly processes, delivering the following benefits:

• Reduced manual handling and improved logistics efficiency

• Elimination of high-altitude stacking, enhancing operational safety

• Reduced pallet deformation and product damage

• Automated interconnection between workshop processes

• Improved space utilization, resolving site capacity constraints

The system enables automated transport, conveying, depalletizing, and AS/RS inbound and outbound operations across machining and washing processes. It significantly improves logistics efficiency and automation levels, reduces labor costs, and enhances overall enterprise automation capability—creating greater long-term value for the company.