Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

Learn MoreAs global supply chains face rising pressure from digitalization, labor shortages, and cost control demands, manufacturers across industries are accelerating their investment in automated warehousing to stay competitive.

Manufacturers in sectors such as pharmaceuticals, food & beverage, electronics, and chemicals are undergoing unprecedented supply chain transformation. Key drivers include:

– Rising SKU complexity and order frequency

– Strict safety and traceability requirements

– Sustainability and space efficiency goals

– Demand for 24/7, error-free fulfillment

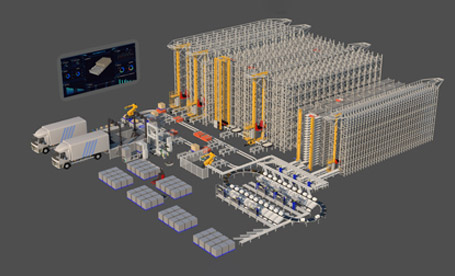

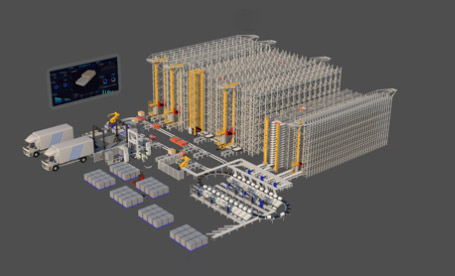

In response, companies are integrating intelligent warehousing systems—such as Automated Storage and Retrieval Systems (AS/RS), pallet shuttle robots, stacker cranes, and Warehouse Management Systems (WMS)—to enable lean, agile, and scalable operations.

With industrial real estate costs increasing globally, maximizing vertical space has become essential. Deli’s smart warehousing solutions utilize high-density racking systems and multi-depth configurations, increasing space utilization by 50–300%. This flexibility enables efficient storage of various SKU sizes and pallet types across diverse industry applications.

Traditional manual processes often cannot keep pace with modern throughput demands. Deli’s systems integrate:

– Pallet shuttle robots

– Stacker cranes

– Conveyor lines

– Vertical lift modules (VLMs)

These technologies work in unison to support 24/7 automated operations, increasing picking speed by 50% or more while cutting labor needs by over 50%. The modular design allows for easy scalability during peak seasons or production expansion.

A smart warehouse is not just physical—it’s digital. By integrating WMS with ERP and MES platforms, manufacturers can eliminate data silos and gain:

– Real-time inventory visibility

– Batch-level tracking and expiry alerts

– Demand-driven replenishment and production planning

– Closed-loop data management for optimized turnover

Deli offers a 3D digital twin central control system, which provides a real-time digital replica of the warehouse and production environment. Managers can monitor, diagnose, and optimize operations across all levels—from material flow to machine performance—resulting in:

– Improved decision-making speed

– Reduced maintenance costs

– Enhanced risk prediction and system uptime

Deli Smart Warehousing has over 1,000 successful AS/RS deployments worldwide, serving sectors including:

– Electronics and semiconductors

– Pharmaceuticals and biotech

– Food & beverage production

– Chemicals and new energy

With end-to-end capabilities—from consulting and design to system integration and after-sales support—Deli provides tailored automation solutions for manufacturers aiming to scale intelligently and sustainably.

Smart warehousing is no longer a future trend—it’s a present necessity for manufacturers pursuing digital transformation, operational excellence, and competitive agility. By adopting high-density automation systems and intelligent software, enterprises can unlock greater value from every square foot, enhance their supply chain resilience, and prepare for long-term, sustainable growth.

Deli Smart Warehousing is committed to enabling this transformation, offering globally proven solutions to help manufacturers make the leap from traditional to intelligent logistics.