Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

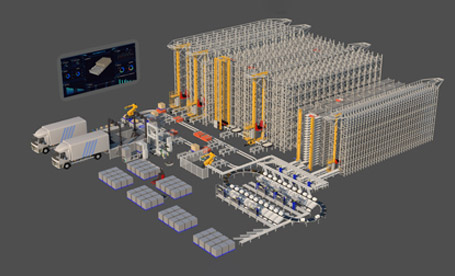

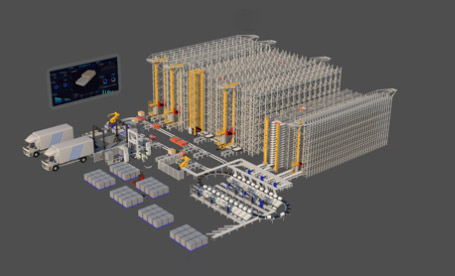

Learn MoreAs demand for lithium batteries grows rapidly across the globe, manufacturers of cathode materials face increasing pressure to improve operational efficiency, storage density, and safety compliance. In response, one leading cathode materials manufacturer partnered with Deli Intelligent Warehousing to implement an advanced automated storage and retrieval system (AS/RS)—designed to optimize warehouse performance, reduce labor costs, and support smart factory transformation.

The client is a major producer of lithium battery cathode materials, including LFP (Lithium Iron Phosphate), NCM (Nickel Cobalt Manganese), and NCA (Nickel Cobalt Aluminum). To support expanding production capacity and streamline logistics, the company sought a high-density, intelligent warehousing system tailored to the material handling requirements of lithium battery manufacturing.

Deli developed a fully integrated solution without altering the existing building structure, including column spacing or ceiling height. The system features:

• Warehouse Management System (WMS)

• Pallet Four-Way Shuttle Robots

• High-Density Multi-Deep Racking

• Conveyor & Vertical Lifter Systems

• Smart Visualization & Control Modules

System Specifications:

• Total footprint: approx. 11,050 m² (170 m × 65 m)

• Storage height: 21 meters

• Total pallet positions: approx. 40,000

• Unit load specification: up to 1,000 kg per pallet

• Pallet size: 1,200 mm × 1,200 mm × 1,360 mm (L×W×H)

• Two warehouse zones: one for raw material inbound and production supply, the other for finished goods storage and outbound handling

• Smart Inventory Management: The WMS enables real-time inventory tracking, inbound/outbound control, production line replenishment, and cycle counting.

• System Interoperability: Seamlessly integrates with upstream MES and ERP systems.

• Optimized Equipment Scheduling: The WCS (Warehouse Control System) assigns the most efficient paths for all robotic and conveyor systems.

• Full Visualization: Digital twin dashboards provide real-time monitoring across all zones.

• Maximized Space Utilization: Vertical storage design significantly increases capacity within the same footprint.

• Automated Material Handling: Robotic shuttle vehicles and lifters ensure fast, accurate transport and retrieval.

• Reduced Labor Costs: Automated operations lower reliance on manual work, increasing efficiency and accuracy.

Lithium battery materials are sensitive to contamination. Deli’s solution includes:

These measures protect product quality and meet strict production standards.

• Slim design to maximize vertical storage density

• 5G and AI communication for collaborative operation

• Obstacle detection and battery monitoring built-in

• Operates in ambient temperatures from –25°C to +40°C

• Manufactured under 100+ quality control procedures for long-term stability

• ±2 mm positioning accuracy for precise handling

• Chain-driven high-speed lift, suitable for 24/7 operations

• Modular design allows easy maintenance and flexible layout

• Integrated with warehouse traffic flow for optimal cycle times

• Achieved nearly 40,000 pallet positions without increasing floor space

• Enabled automated and intelligent storage for raw materials, work-in-progress, and finished goods

• Improved material turnover speed and warehouse integration with production, achieving true smart logistics

With over 1,000 AS/RS projects implemented worldwide, Deli Intelligent Warehousing is a trusted solution partner for manufacturers in industries such as new energy, chemicals, pharmaceuticals, food, and general manufacturing. Deli offers:

• End-to-end service: design, integration, commissioning, and after-sales support

• In-house R&D and manufacturing for software and equipment

• Scalable, modular solutions tailored to diverse needs

Contact our team to learn how Deli can help you transform your warehouse into a competitive advantage.