Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

Learn MorePharmaceutical warehousing is defined by product integrity, traceability, and process discipline. Beyond throughput, operations must control status segregation, support lot/batch rules, and maintain inspection-ready records—especially in temperature-controlled and high-mix environments.

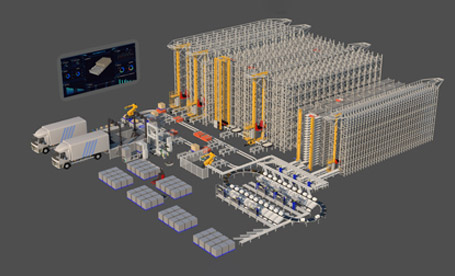

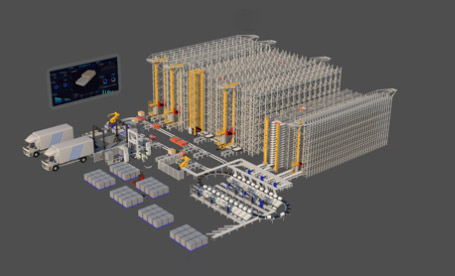

An integrated automated storage and retrieval system (AS/RS)—combined with WMS/WCS and verification points—can help reduce manual touches, lower mix-up risk, and improve flow stability during peak waves.

Pharma storage often requires monitored conditions (e.g., temperature in °C) and consistent handling procedures to protect quality and support documented operations.

Quarantine, released, rejected, and returned goods must be clearly separated—along with category and risk-based zoning—to avoid cross-mix and support compliant workflows.

Operators need a reliable data layer for lot/batch identity, location, movement history, and exceptions—with a clear audit trail.

A modern Warehouse Control System (WCS) coordinates shuttles, stacker cranes, lifts, conveyors, and transfer stations in real time. Scheduling logic can reduce task conflicts, balance queues at handover points, and prioritise urgent replenishment or dispatch tasks—helping minimise dwell time caused by congestion or unbalanced task release.

A pharma-oriented Warehouse Management System (WMS) typically enforces:

Digital visualisation and pre-implementation simulation can help validate flow assumptions, identify bottlenecks early, and support smoother commissioning and continuous improvement.

Depending on product profile and throughput targets, systems may include:

DELIECN delivers automated warehousing and intralogistics solutions integrating AS/RS equipment with WMS/WCS and operational visibility tools—supporting projects from system design and commissioning to lifecycle service.