Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and Consulting: With decades of experience, DELIECN provides intelligent warehousing & logistics solutions and consulting services for clients across a wide range of industries.

Learn More

Solutions and consulting: DELIECN has decades of experience providing logistics & warehouse automation for the key industries.

Learn More

Drum packaging (steel, plastic, fibre) is widely used in chemicals, pharmaceuticals, food ingredients, and industrial manufacturing. At scale, drum warehousing often faces recurring constraints: space efficiency, handling safety, and inventory accuracy—especially when materials are heavy, sensitive, or require controlled operating discipline.

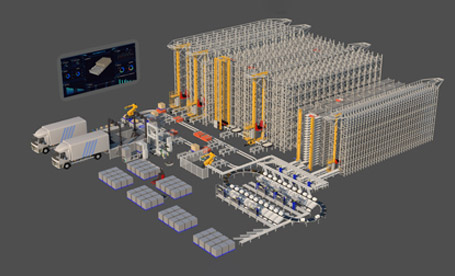

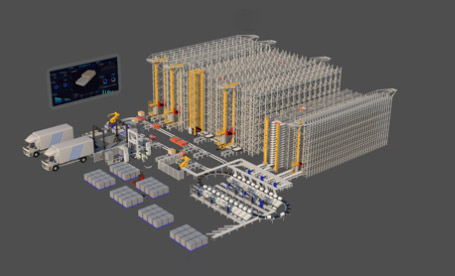

A pallet-based high-density automated storage and retrieval system (AS/RS), integrated with WMS/WCS, helps standardise drum handling, reduce manual touches, and stabilise material flow from inbound receipt to production supply—without relying on operator experience as the primary control mechanism.

Why Drum Warehousing Becomes Complex

• Space loss in conventional storage: wide aisles, conservative stacking, and inconsistent placement reduce effective capacity.

• Handling risk: frequent forklift moves and manual counting increase exposure to impacts, instability, and product loss.

• Operational variability: different drum formats and process requirements increase misplacement and retrieval delays.

• Inventory discrepancies: manual tracking can lead to data gaps that affect planning and production continuity.

• Risk-based control needs: certain materials require defined zoning, controlled access, and disciplined workflows (site-specific).

An Engineering-Ready Approach

1) Pallet standardisation for drum handling

Drums are handled as palletised units to improve stability and enable predictable interfaces across storage, transfer, and downstream supply.

2) High-density pallet AS/RS

Two common options are used depending on throughput and density targets:

• Stacker crane AS/RS for aisle-based pallet handling and structured flow

• Four-way shuttle AS/RS for dense multi-lane storage and flexible access strategies

3) WMS + WCS integration

• WMS governs inventory logic, locations, and rule-based controls (e.g., status segregation and batch/lot rules where required).

• WCS orchestrates equipment in real time—cranes/shuttles, lifts, conveyors, and transfer stations—to reduce task conflicts and balance queues at handover points.

4) Optional interfaces for reduced manual touches

Where operations require it, the AS/RS can integrate with:

• AGVs for warehouse-to-production transport

• automated handling cells (e.g., gantry/truss manipulators) for palletising/depalletising

5) Zoning and access control support

• “Supports zoning and controlled task release based on site-defined material classes, status, and operating rules.”

• “Supports controlled access logic and traceable movements via system records.”

Reference Projects

Case 1: Stacker Crane AS/RS for Drum-Based Raw Materials (Non-Ferrous Manufacturing)

• AS/RS height: 17.7 m; 10 levels

• 2,000+ effective pallet positions

• Approx. 2,000 t storage capacity (project-reported)

• Approx. 5× space utilisation improvement versus the previous conventional setup (project-reported)

• WCS coordinated conveyors, AGVs, and handling equipment to support automated receiving, storage, and outbound feeding, with functional zoning to reduce cross-traffic.

Case 2: Four-Way Shuttle AS/RS for Welding Wire Drums

A pallet four-way shuttle AS/RS integrated shuttles, lifts, conveyors, palletising/depalletising, WMS/WCS, and AGV handover to production. A 1,000 kg-class handling solution supported palletising and depalletising before dense storage and downstream workstation supply.

About DELIECN

DELIECN provides automated warehousing and intralogistics solutions integrating AS/RS equipment with WMS/WCS and site implementation services—tailored to site-specific operational and safety requirements.